Survey - Digital Twins & Separation

In the autumn 2023, MySep carried out a survey to gather insights on the emerging use of Simulation-based Digital Twins in the oil and gas industry.

The sections below provide more information on the people surveyed and a preview of the results.

For a lively walk through the survey context and insights .....

Please launch the video linked below:

Industry Context

The industry is abuzz with discussions about digital twins, a topic that has dominated several major international conferences in recent years. Digital twins generally fall into two distinct categories:

- Asset Representation Digital Twins: These provide a detailed representation of a physical asset, including its key components, specifications, and often the 3-D spatial relationships between them rendered with visualization.

- Simulation-Based Digital Twins: These are characterized by their simulation-based representation of process behaviour. They can be developed for relatively discrete processes, such as an oil and gas production platform topsides process, or for much larger scale processes, such as a full refinery-wide model.

Our survey focuses on the second type, the simulation-based digital twins.

Survey Responses

MySep’s Digital Twin Survey captured a diverse group of participants, including both existing customers and representatives of unaffiliated organizations.

Here's a general breakdown of our respondents:

Industry Representation:

- 42% were employed by companies providing engineering services to the industry.

- 41% were working for process operating companies.

Job Titles:

- Nearly 30% of respondents held managerial positions.

- One-third of respondents had "process" or "engineer" in their job titles.

- We also received responses from a notable number of company directors and vice presidents.

This diverse feedback provides valuable insights into the perspectives of key stakeholders in our industry.

Companies Represented

Responses were received from representatives of over 80 organizations. Over 90% were from private or publicly-traded companies, with one or two survey returns from individuals representing educational institutions.

Below is a sample of the companies participating:

Existing MySep Customer

- Bechtel

- BP

- Conoco Phillips

- Harbour Energy

- Marathon Petroleum

- Petronas

- SBM Offshore

- Valero

Non-Customers

- ADNOC Offshore

- Black & Veatch

- BW Offshore

- CETCO Energy Services

- Inprocess Technology & Consulting

- NOV

- OMV

- Seplat Energy

Top Applications for Digital Twins

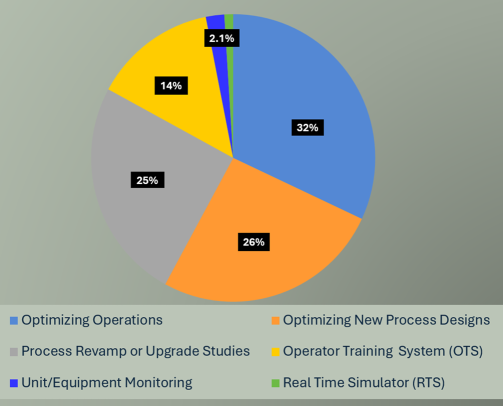

As an example of analysis of the survey, consider responses to the survey question:

"Which process simulation/digital twin applications do you consider most important?"

Results can be seen in the accompanying pie chart.

Among the various applications suggested, the highest level of support was for:

"Optimization of Operations."

Other Results & Comments

89% of respondents agree that having accurate separator performance predictions is valuable in a process digital twin.

74% of respondents were aware of the MySep Engine software, (which provides accurate separator gas-liquid performance prediction inside the simulation platforms used for dynamic and steady-state process digital twins).

Of those responding, 80% reported that their company does have a digitalization strategy.

How MySep Software Supports Digital Twins

MySep Engine embeds in the simulation software platforms allowing proper gas-liquid separation modelling in dynamic and steady-state process Digital Twins.

MySep Studio allows the construction of physically-representative separator models which reflect the process behaviour of actual equipment installed in process facilities. These models can represent the arrangements and separation behaviour of all common types of separation “internals.”

References to MySep and Digital Twins

Turbo-charging LNG production in an uncertain world through the use of Digital Twins.” MySep’s Tom Ralston, and Philip Hicks of Pravo Consulting, describe how a digital twin, with MySep Engine embedded, can help identify and resolve bottlenecks in LNG processes. A technical article published in the March 2023 edition of LNG Industry journal.

LNG Digital Twin: Review MySep Case Study

Link to full article: LNG Industry Journal-March 2023

KBC and MySep jointly publish a white paper: Digital twin optimises FCC operations for real separator behaviour. Rodolfo Tellez-Schmill, KBC, Tom Ralston, MySep and Wim Moyson, MySep; show in detail how a digital twin with rigorous separator modelling can help optimise operations and avoid un-planned shut-downs. Using Petro-SIM, MySep Engine and MySep Studio software, different retrofit options for existing separation vessels are explored, to handle upgraded throughput and increased stream volatiles.

Reference link: Petroleum Technology Quarterly (PTQ), Q2 2022, P27-31

Digital Twin to Determine the Adequacy of FCC Unit Separators with Changing Operating Conditions: KBC’s Rodolfo Tellez-Schmill, MySep’s Wim Moyson and Tom Ralston, discuss how a digital twin incorporating rigorous separator modelling can help optimise FCC operations. With over 60 attending the live event, the presentation showed how to deal with variations in operating conditions arising from environmental drivers and market trends towards increased petrochemical production. A Digital Twin in Petro-SIM was enhanced with MySep Engine separator models. MySep Studio was used to provide retro-fit improvements to the separators in the Wet Gas Compression section of the FCC. Now available to view On-Demand.

KBC on-demand webinar replay: View On-demand Webinar

MySep Margin Optimization

This 3 minute video illustrates how MySep technology helps Oil & Gas companies to optimize operations for increased revenue and margin. It is based around a production Digital Twin with MySep Engine modelling embedded in a steady state simulation. The example shows how optimizing separation performance on a facility, of modest scale, can can yield additional revenue of over $300 million per annum.

The MySep team would like to record our sincere appreciation to all those industry practitioners, and other interested parties, who were kind enough to submit their views.